We print into the open oxidation layer of aluminium using screen printing or digital printing. After the subsequent sealing of the oxidation layer on the surface of the printed object in a warm bath, a first-class hardness is achieved.

Properties of anodised labels

- High weather resistance

- Resistance to mechanical influences and high temperatures

- Resistance to chemical influences

- Permanent colour fastness

- Suitable for indoor and outdoor use

Printing and colouring:

- Underwater colours (basic shades: black, red, yellow, green, orange and blue)

- Digital printing (unlimited colours)

- Screen printing

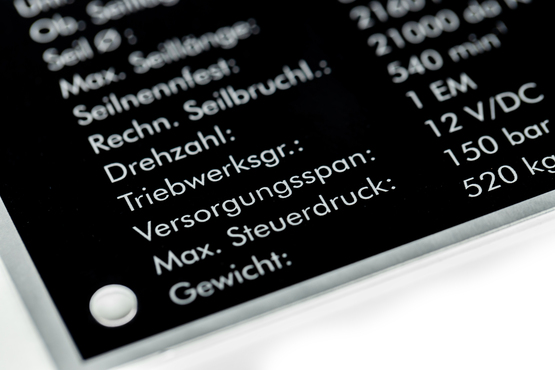

Offer of anodised labels

The base surface of the aluminium sheets is matt silver. The labels are available in various thicknesses, most commonly 0.5 and 1 mm. The overall size and shape are then designed according to the customer's requirements.

We are able to produce small batch orders up to large series.

Our anodized label mounting options are:

- Self-adhesive - the label is affixed with a powerful double-sided adhesive tape with a liner

- Labels with mounting holes: they can have holes for screws, cut-outs or windows. We are also able to offer labels with differently rounded corners.

3D parts anodising

With this technology we can offer our customers anodizing of supplied 3D parts.

We can offer transparent anodizing or painting of parts (basic colours - black, blue, red, orange, yellow and green). Our anodizing baths are 2 x 1 m and therefore we can anodize even quite large parts. By anodising 3D parts we achieve high durability, just like anodised labels.